Products

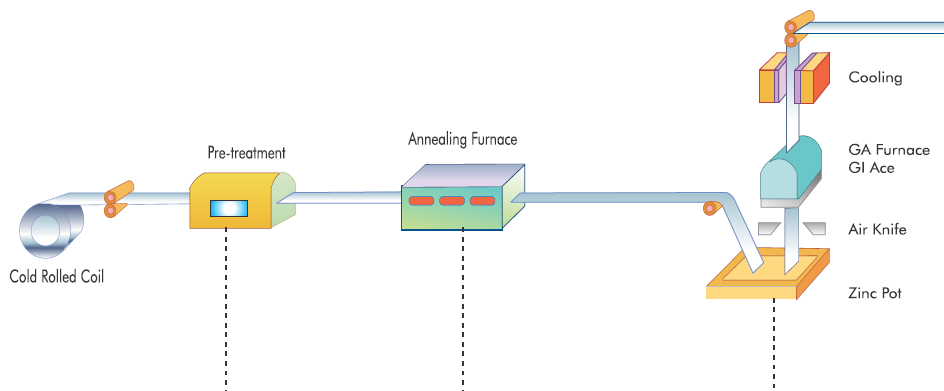

Manufacturing Process

| Classification | POSCO Maharashtra CGL | |

| Date of Operation | May, 2012 | |

| Capacity (Ton/year) | 450,000 | |

|

Available Size

|

Thickness (mm) | 0.35~2.30 |

| Width (mm) | 800~1,860 | |

| Weight (Ton) | Max 30 | |

|

Coating Weight (g/m²)

|

GA | Both side 60~120 |

| GI | Both side 60~600 | |

ECL

The main purpose of Electrolytic Cleaning is to be remove the lubricant oil and dirt left on cold rolled strip before annealing.

Annealing

A steel sheet having a pre-treatment to secure for some mechanical characteristics after being re-crystallized during the annealing process.

Hot Dip Galvanizing

Zn is coated onto the surface of a steel sheet after passing the annealing furnce in the Zinc Pot, and then the targeted coating weight is achived by spraying some high pressure air from the air knife.

| Classification | POSCO Maharashtra CGL |

| Product Grade | Cummercial, Drawing, Deep Drawing, Extra Deep Drawing, Structural, High-strength Steel, BH, AHSS (DP590) |

| Chemical Treatement | Oiling, Cr-Free, Phosphate, Chromoted |

| Inner Diameter (mm) | 508 (20")/610 (24") |

| Coil Weight | 5.0~25.0 MT |

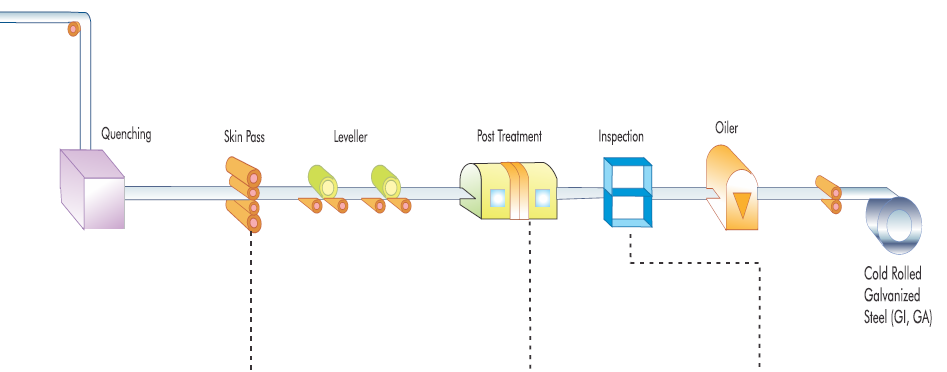

Skinpass

In order to improve the mechanical properties, suppress yield point elongation, strip shape correction to the secure the flat shape, to the obtain desired roughness, the steel sheet should be passed through a skin pass mill.

Post Treatment

In order to prevent any white rust which can occur on the surface due to activated zinc, to improve the corrosion resistance the surface is coated with Cr-free resin / chromate.

Inspection

The equipment at the exit section are composed surface defect detector, Inspection table and Oiler equipment. The Product are inspect and judge systematically, whether such products are appropriate to client company or not.